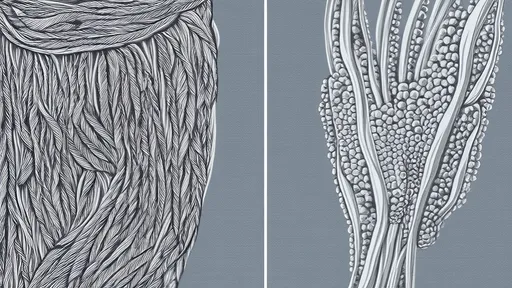

The molecular basis of dough extensibility in high-gluten flour is deeply rooted in the unique properties of wheat gluten proteins, particularly the ratio between gliadin and glutenin. These two protein fractions form a viscoelastic network when hydrated, creating the structural backbone that gives wheat dough its characteristic stretch and strength. While gliadins contribute primarily to viscosity and extensibility, glutenins are responsible for elasticity and dough strength. The interplay between these components determines the functional performance of flour in baking applications.

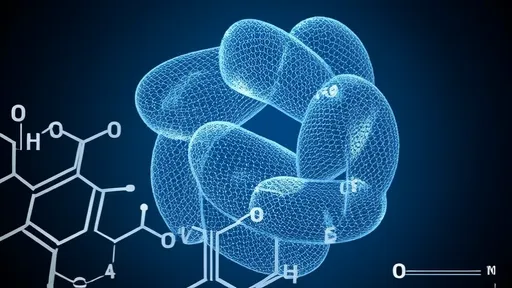

High-gluten flours typically contain a higher proportion of glutenin relative to gliadin, which explains their superior dough strength and elasticity. Glutenins are polymeric proteins consisting of high molecular weight (HMW) and low molecular weight (LMW) subunits linked by disulfide bonds. The HMW glutenin subunits are particularly crucial as they form the backbone of the gluten network through interchain disulfide bonds. The length and composition of these polymers directly influence the rheological properties of dough, with longer polymers generally associated with greater elasticity and dough strength.

The genetic makeup of wheat varieties plays a fundamental role in determining the glutenin-to-gliadin ratio. Modern wheat breeding has focused on selecting cultivars with specific HMW glutenin subunit compositions to optimize dough quality. For instance, the presence of certain HMW subunits like Dx5+Dy10 has been correlated with superior bread-making quality due to their ability to form extensive gluten networks. This genetic variability explains why different wheat varieties produce flours with varying performance characteristics despite similar protein content.

At the molecular level, the extensibility of high-gluten flour dough can be understood through the dynamic rearrangement of gluten proteins during mixing and resting. When flour is hydrated and mixed, the glutenin polymers align and form temporary cross-links through non-covalent interactions and sulfhydryl-disulfide interchange reactions. This creates a three-dimensional network that can stretch and recoil. The gliadin molecules, being monomeric, act as plasticizers within this network, allowing for extension without immediate rupture.

The unique rheological behavior of high-gluten dough becomes particularly evident during the bread-making process. During fermentation, the expanding gas cells stretch the gluten network, which must maintain sufficient elasticity to prevent collapse while allowing gradual expansion. The glutenin-rich network in high-gluten flour provides the necessary resistance to deformation, while the gliadin fraction ensures the dough doesn't become too rigid. This balance is critical for achieving optimal oven spring and final product volume.

Environmental factors and growing conditions can significantly impact the gluten protein composition in wheat. Nitrogen availability during growth, for example, has been shown to influence the synthesis of gluten proteins, often increasing the glutenin content relative to gliadin. Similarly, water stress during specific growth stages may alter the expression of certain glutenin subunits. These variations explain why the same wheat variety can produce flour with different baking qualities when grown under different conditions.

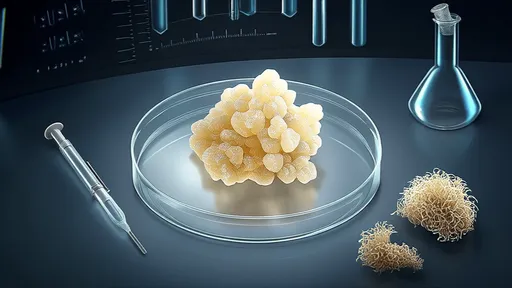

Recent advances in analytical techniques have allowed for more precise characterization of gluten protein composition and its relationship to dough functionality. Size-exclusion high-performance liquid chromatography (SE-HPLC) has become particularly valuable for quantifying the relative amounts of polymeric and monomeric proteins in flour. These analytical methods, combined with advanced rheological testing, provide millers and bakers with tools to predict flour performance based on its molecular composition.

The industrial processing of high-gluten flour also affects its molecular properties. Milling techniques that minimize starch damage and preserve protein integrity tend to produce flours with better gluten functionality. Additionally, oxidation treatments sometimes used in commercial flour production can modify the sulfhydryl groups on gluten proteins, affecting their ability to form disulfide bonds and consequently altering dough properties.

Understanding the molecular basis of dough extensibility has important implications for both traditional baking and modern food technology. In artisanal bread making, bakers can select flours with specific gluten protein ratios to achieve desired handling characteristics and final product textures. For industrial applications, this knowledge facilitates the development of specialized flour blends and processing aids that optimize dough performance in high-speed production environments.

Looking forward, research continues to explore ways to manipulate gluten protein composition through both conventional breeding and biotechnological approaches. The goal is to develop wheat varieties with precisely tailored gluten properties that meet the evolving needs of diverse baking applications while also addressing growing demands for consistent quality in varying climatic conditions.

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025