The dairy industry has long relied on centrifugal separation as a fundamental process for isolating cream from raw milk. At the heart of this mechanical marvel lies an often-overlooked biological component: the milk fat globule membrane (MFGM). This intricate protein-lipid structure not only determines the efficiency of cream separation but also holds untapped potential for nutritional and industrial applications.

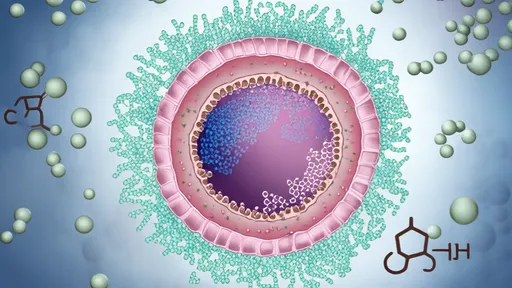

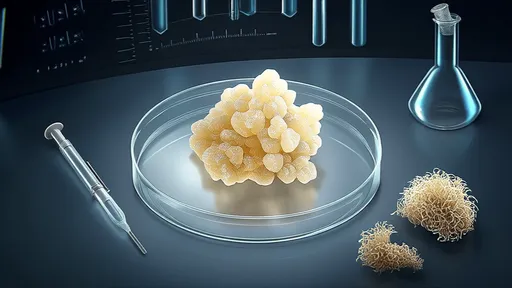

When fresh milk emerges from the udder, its fat exists as microscopic globules suspended in aqueous solution. Each fat droplet, ranging from 0.1 to 15 micrometers in diameter, comes wrapped in a tri-layer membrane that prevents coalescence. This natural packaging system, evolved over millennia of mammalian biology, contains specialized proteins that maintain emulsion stability during the milk's journey from farm to processing plant.

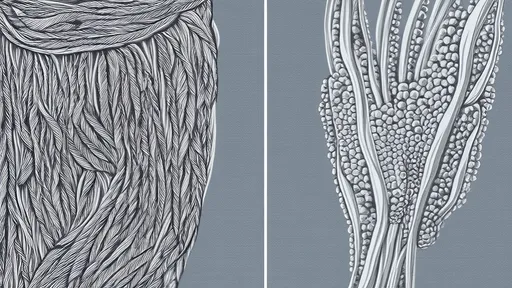

The centrifugal separation process capitalizes on density differences between milk components. As spinning forces exceed 5,000 times gravity, denser skim milk moves outward while buoyant cream concentrates inward. However, the MFGM proteins play a decisive role in this partition. Their surface properties determine how readily fat globules release from the aqueous phase, with certain membrane proteins acting like molecular handles for mechanical separation.

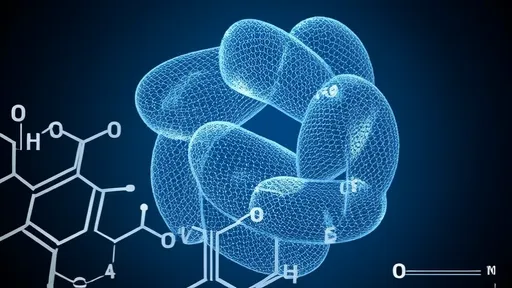

Recent cryo-electron microscopy studies reveal the MFGM's astonishing complexity. The primary structural proteins - including butyrophilin, adipophilin, and xanthine oxidase - form a dynamic mesh that responds to mechanical stress. During centrifugation, these proteins undergo conformational changes that weaken their grip on the fat core, allowing cleaner separation than simple density differences would predict.

Dairy engineers have observed that raw milk with intact MFGMs separates more efficiently than homogenized or processed milk. This phenomenon led to the discovery that industrial homogenization, which shreds fat globules and redistributes membrane material, actually complicates later separation steps. Modern creameries now optimize their pre-processing to preserve MFGM integrity, recognizing these proteins as natural separation enhancers.

The temperature dependence of cream separation also traces back to MFGM behavior. Below 40°C, the membrane proteins maintain a rigid structure that resists mechanical disruption. As temperatures approach 50°C during standard processing, key proteins begin to denature, reducing interfacial tension and permitting cleaner fat separation. This thermal transition point has become critical for optimizing industrial centrifugation parameters.

Beyond separation efficiency, MFGM proteins influence cream quality. Their phospholipid-rich composition contributes to cream's viscosity and whipping properties. Some creameries now monitor specific MFGM protein ratios as quality markers, recognizing that optimal membrane composition yields cream with superior texture and stability for premium products.

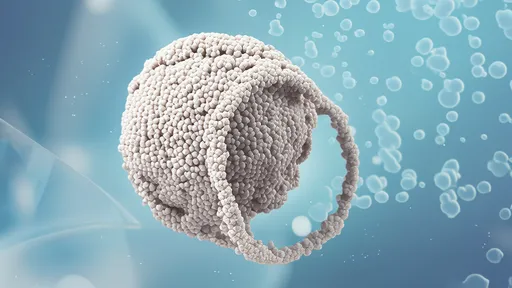

Emerging research suggests MFGM proteins may facilitate fractionation of milk fat components. Certain membrane-associated proteins show affinity for specific triglyceride fractions, potentially enabling targeted separation of milk fat subsets. This discovery could revolutionize specialty fat production, allowing dairy processors to tailor cream compositions for specific culinary or industrial applications.

The dairy industry's growing understanding of MFGM proteins has spurred innovation in centrifuge design. New generation separators incorporate features that gently handle the membrane structure, preserving its functional properties while achieving superior separation. Some advanced models even adjust rotational dynamics based on real-time MFGM protein sensors, optimizing performance for each batch's unique characteristics.

Environmental considerations are also driving MFGM-focused improvements. By enhancing separation efficiency through better utilization of these natural proteins, modern dairies reduce energy consumption per unit of cream produced. Some facilities report 15-20% energy reductions simply by optimizing processes around MFGM behavior rather than relying solely on mechanical force.

Nutritional science has begun recognizing the value of intact MFGM proteins in dairy products. While traditional processing often discarded these components with the skim fraction, new techniques allow their recovery and recombination with cream. This approach not only improves product functionality but also preserves bioactive proteins with potential health benefits, creating value-added cream products.

Looking ahead, genetic research may unlock further advancements. Scientists are investigating bovine genetic variants that produce MFGM proteins with enhanced separation characteristics. Selective breeding or bioengineering could someday yield milk optimized for industrial processing while maintaining all-natural credentials - a potential game changer for the dairy industry.

The humble milk fat globule membrane, long considered mere packaging material, has emerged as a critical factor in dairy processing. Its protein components represent a perfect marriage of biological design and industrial utility, demonstrating how nature's solutions often surpass human engineering. As research continues, these microscopic membrane proteins may well hold the key to the next generation of dairy innovations.

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025