The world of food science constantly seeks to understand the intricate relationships between chemical composition and functional properties. Among these, the gelling behavior of pectin in jams and jellies stands as a fascinating case study. While numerous factors influence texture, the degree of esterification (DE) emerges as a pivotal chemical determinant of gel strength. This molecular characteristic doesn't merely affect consistency—it dictates the very architecture of the gel network, influencing everything from spreadability to mouthfeel.

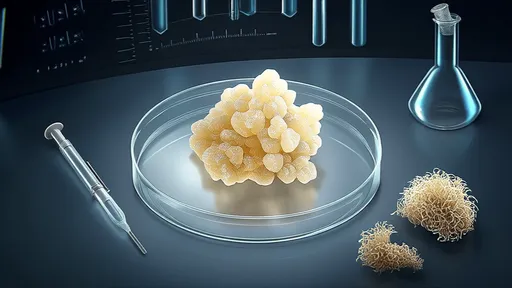

Pectin molecules, those complex polysaccharides found in plant cell walls, possess a backbone of galacturonic acid units. What makes them particularly interesting is their carboxyl groups, which may remain free or become esterified with methanol. The proportion of these esterified groups defines the degree of esterification. High-methoxyl pectins (with DE above 50%) and low-methoxyl pectins (DE below 50%) behave as entirely different gelling agents, following distinct mechanisms that respond to different environmental conditions.

The chemistry behind high-methoxyl pectin gels reveals a delicate dance between sugar, acid, and the pectin molecule itself. In jams and traditional jellies, the high DE pectins form networks through hydrophobic interactions and hydrogen bonds. The abundant methyl esters prevent excessive charge repulsion between chains, allowing the molecules to associate in what scientists describe as "junction zones." These zones require the presence of soluble solids (typically 55-85% sugar) and a pH between 2.8 and 3.5 to stabilize. The higher the degree of esterification within this range, the more readily these interactions occur, generally resulting in firmer gels at equivalent concentrations.

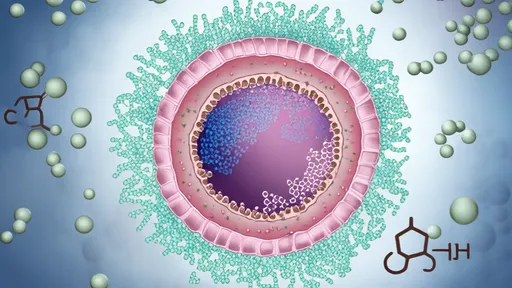

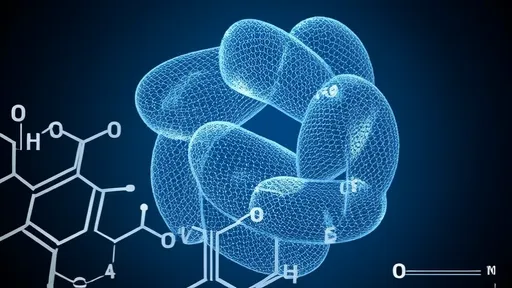

Contrast this with low-methoxyl pectins, where the gelation story takes a different turn. With fewer methyl groups, the negatively charged carboxyl groups dominate the behavior. These pectins form gels through ionic bridges, typically with calcium ions, rather than through sugar-acid mediation. The calcium ions interact with the carboxyl groups of different pectin chains, creating what's known as the "egg-box" model of cross-linking. Interestingly, the optimal gel strength for low-methoxyl pectins often occurs at intermediate DE values (30-40%), where there's sufficient charge for calcium binding but enough hydrophobicity to contribute to network stability.

Food technologists have long observed that pectins with very high DE (above 70%) tend to form gels more rapidly but with less thermal stability. The rapid set can be advantageous for certain applications where pre-gelation must be avoided during processing. Conversely, pectins with moderate DE (50-70%) demonstrate slower setting times, allowing for better handling during production while developing stronger final gels. This time-dependent aspect of gel formation directly impacts industrial processes, influencing everything from filling temperatures to packaging requirements.

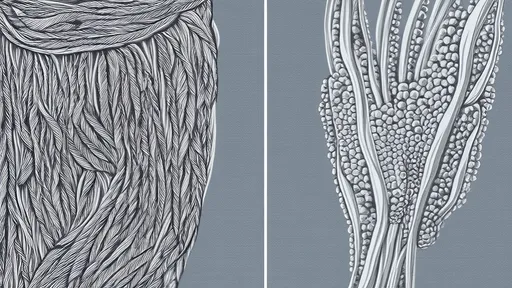

The relationship between DE and gel strength isn't linear—it's profoundly influenced by the pectin's molecular weight and distribution of esters along the chain. Pectins with block-wise distribution of ester groups (where unesterified regions cluster together) tend to form stronger gels than those with random distribution at similar DE values. This occurs because the blocks can participate more effectively in junction zone formation. Advanced analytical techniques like nuclear magnetic resonance (NMR) spectroscopy now allow manufacturers to characterize this pattern precisely, enabling tailored pectin products for specific applications.

Environmental factors interact with DE to produce surprising effects. For instance, in reduced-sugar products where high-methoxyl pectins might struggle to form adequate gels, careful adjustment of DE can compensate. Some mid-range DE pectins (60-65%) demonstrate remarkable versatility, forming acceptable gels across a broader pH range than their higher DE counterparts. This adaptability becomes crucial when dealing with fruits that have naturally varying acid contents or when developing products with alternative sweeteners that might interfere with traditional gelling mechanisms.

The food industry's shift toward clean-label products has renewed interest in pectin's natural gelling properties. Rather than relying on additives to modify texture, manufacturers now carefully select pectins with specific DE profiles to achieve desired consistencies. A strawberry jam might use a high-DE pectin for that classic spoon-standing texture, while a fruit preparation for yogurt could employ a low-DE variant for softer, more spoonable consistency. This precision application of pectin chemistry represents a quiet revolution in product development.

Recent research has uncovered nuances in how DE affects not just gel strength but also syneresis—the undesirable release of liquid from gels. High-DE pectins generally exhibit less syneresis than low-DE types when used in traditional high-sugar systems. However, in low-sugar applications, certain mid-range DE pectins show superior water-holding capacity. These findings challenge old assumptions and open new possibilities for optimizing product shelf life and quality.

As analytical methods grow more sophisticated, our understanding of DE's role continues to evolve. What once seemed like a straightforward relationship between esterification and gel strength now appears as a complex interplay of multiple factors. The food industry's ability to measure and control pectin DE with increasing precision promises continued innovation in product textures, from artisanal preserves to large-scale industrial food production. This unseen molecular characteristic quietly shapes our sensory experience of countless products, proving that in food science, the smallest chemical details often make the biggest difference.

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025