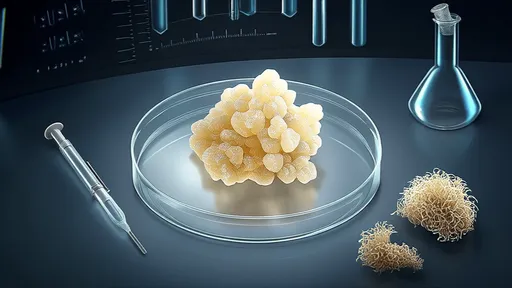

The art of rock sugar production is a delicate balance between science and tradition, where the precise control of saturation levels determines the quality, size, and clarity of the final crystals. Unlike ordinary sugar refining, rock sugar formation relies on a carefully orchestrated supersaturation process that encourages the growth of large, well-defined crystals over time. This centuries-old technique transforms simple syrup into translucent gems of sweetness through a patient dance of temperature, concentration, and time.

At the heart of rock sugar creation lies the fundamental principle of saturation control. When a sugar solution reaches its saturation point - that precise moment when the liquid can no longer dissolve additional sugar molecules at a given temperature - the foundation for crystallization begins. However, true mastery comes in pushing the solution beyond this point into supersaturation, where the unstable solution becomes primed for crystal formation. Artisans have learned through generations that the degree of supersaturation directly influences whether one obtains many small crystals or fewer, larger specimens.

The temperature gradient plays perhaps the most crucial role in managing saturation levels. As hot syrup cools, its capacity to hold sugar in solution decreases dramatically. Skilled producers use this thermal dependence to their advantage, initiating the process with near-boiling syrups that can achieve extraordinary concentrations. The gradual cooling that follows must be carefully regulated; too rapid cooling leads to uncontrolled nucleation and a gritty texture, while too slow cooling may prevent crystallization altogether. Traditional methods often rely on ambient temperature fluctuations across seasons, with winter production favored for its natural cooling advantages.

Impurity management represents another critical factor in saturation control. While one might assume absolute purity would yield the best results, experienced rock sugar makers understand that trace minerals and organic compounds actually serve as beneficial nucleation sites. These impurities, carefully maintained at optimal levels, provide starting points for crystal growth without causing excessive competition between developing crystals. The art lies in balancing enough impurities to initiate controlled crystallization while maintaining sufficient purity for the crystals to grow transparent rather than cloudy.

Evaporation rates work in concert with temperature to govern saturation dynamics. Open-air evaporation, still practiced in traditional workshops, allows for gradual water loss that maintains the syrup at ideal supersaturation levels for extended periods. Modern production facilities may use controlled vacuum evaporation to achieve similar results more predictably. In both cases, the goal remains consistent: to remove water at a pace that keeps the solution in the metastable zone of supersaturation where existing crystals grow without spawning excessive new nuclei.

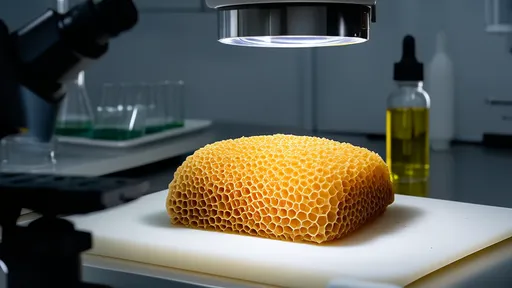

The vessel geometry and material significantly influence local saturation conditions. Wide, shallow pans promote uniform evaporation across the solution surface, while the choice of copper versus stainless steel affects heat distribution and minor chemical interactions with the syrup. Traditional bamboo sticks or cotton strings suspended in the syrup provide ideal surfaces for crystal initiation, their porous nature creating microenvironments where saturation levels differ slightly from the bulk solution. These subtle variations trigger the first orderly deposition of sugar molecules that will eventually grow into substantial crystals.

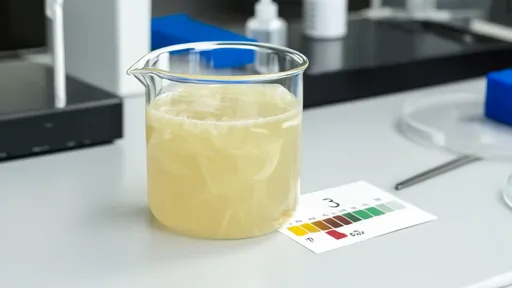

Monitoring saturation represents an ongoing challenge throughout the production process. While refractometers provide precise brix measurements, many veteran producers still rely on visual cues and tactile tests developed over generations. The way syrup drips from a spoon, the specific viscosity at different temperatures, and even the sound of bubbling syrup all contribute to the artisan's assessment of saturation status. This sensory knowledge, often undocumented but meticulously preserved, allows for real-time adjustments that no instrument can fully replicate.

Time acts as both ally and adversary in saturation control. Extended periods at optimal supersaturation allow for magnificent crystal growth, but also increase the risk of secondary nucleation or contamination. The finest rock sugar products often result from interrupted processes - periods of growth followed by brief adjustments to the syrup concentration. This stop-start approach, sometimes spanning weeks, builds layer upon layer of perfectly aligned sucrose molecules, creating that signature glass-like clarity and satisfying hardness.

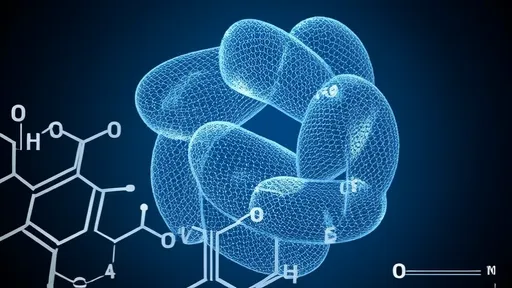

Modern analytical techniques have revealed fascinating details about the molecular dynamics during rock sugar formation. At the ideal supersaturation level, sugar molecules in solution begin to organize into preliminary clusters that eventually develop into stable crystal nuclei. The concentration gradient around growing crystals creates localized zones of varying saturation that influence neighboring crystals' growth patterns. Understanding these microenvironments has led to improved production methods that yield more consistent crystal sizes and shapes.

The final stages of rock sugar production demonstrate saturation control's importance most dramatically. As the mother liquor becomes depleted of sugar molecules, the remaining solution must be maintained at just the right saturation to allow final crystal faces to form perfectly without initiating new growth. This terminal phase often determines whether crystals will exhibit smooth, mirror-like facets or develop imperfections. The decision of when to separate crystals from the residual syrup - a moment determined by subtle saturation changes - makes the difference between premium quality and mediocre product.

Regional variations in rock sugar production highlight how different cultures have adapted saturation control to local conditions. Southern Chinese methods favor slightly higher initial concentrations that yield chunkier crystals, while Middle Eastern traditions often produce more delicate, smaller crystals through modified evaporation techniques. These geographical differences showcase how environmental factors - from humidity to altitude - interact with saturation principles to create distinctive products.

Contemporary food science continues to refine our understanding of saturation's role in rock sugar quality. Advanced monitoring systems can now track minute changes in solution concentration, allowing for unprecedented control over crystal growth. However, many premium producers maintain that the human element - the artisan's intuition honed through years of observation - remains irreplaceable in achieving truly exceptional results. This marriage of ancient wisdom and modern technology points toward an exciting future for this traditional sweetener.

The market's growing appreciation for artisanal foods has brought new attention to traditionally made rock sugar. Consumers increasingly recognize how precise saturation control translates to superior melting characteristics, flavor release, and aesthetic appeal. As demand grows for authentic, carefully crafted ingredients, the ancient science of saturation management in sugar crystallization enjoys a well-deserved renaissance, connecting modern tables to centuries of culinary tradition.

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025