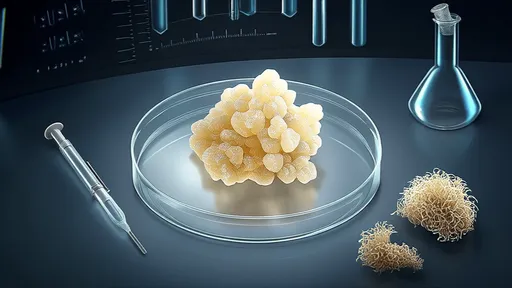

The culinary world has long revered dried shiitake mushrooms for their intense umami flavor, a characteristic largely attributed to their high concentration of flavor nucleotides. Recent research has shifted focus toward optimizing extraction methods to harness these compounds efficiently, revealing both challenges and breakthroughs in the process.

At the heart of shiitake's savory profile are nucleotides like guanylate (GMP) and adenylate (AMP), which synergize with glutamates to amplify umami. Unlike fresh mushrooms, the drying process concentrates these compounds through enzymatic and Maillard reactions, creating a potent flavor reservoir. However, extracting these nucleotides at scale while preserving their integrity requires precise control of variables such as temperature, pH, and extraction duration.

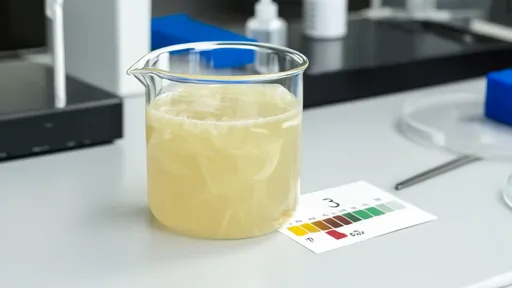

Traditional hot water extraction remains the industry standard, but studies show its limitations. Prolonged heating above 80°C degrades heat-sensitive nucleotides, while insufficient extraction time leaves up to 30% of compounds unutilized. Researchers at Japan's Umami Science Institute demonstrated that a two-stage approach—starting with a 60°C soak to activate endogenous enzymes, followed by a brief 75°C extraction—yields 22% more GMP than conventional methods.

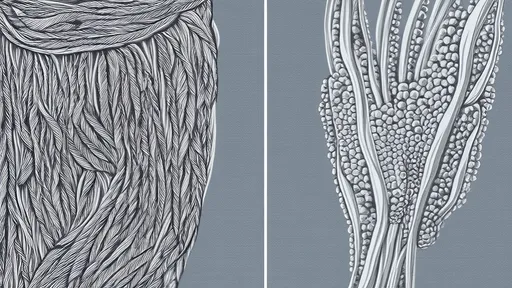

Emerging technologies are pushing boundaries further. Ultrasound-assisted extraction (UAE) disrupts cell walls mechanically, releasing nucleotides at lower temperatures. Trials comparing UAE to thermal methods revealed a 40% reduction in processing time and 15% higher AMP recovery. Similarly, enzymatic pretreatment with cellulase and β-glucanase before extraction increased total nucleotide yield by 35% by breaking down chitin-rich cell walls.

The water-to-mushroom ratio emerges as another critical factor. Counterintuitively, higher ratios (20:1) don't necessarily improve yields. A 2023 study published in Food Chemistry identified an optimal 12:1 ratio that balances compound solubility with practical concentration for industrial applications. This finding challenges the "more solvent equals better extraction" assumption prevalent in early research.

Post-extraction stabilization presents its own hurdles. Nucleotides are prone to enzymatic degradation by phosphatases present in mushroom tissue. Rapid cooling to 4°C immediately after extraction preserves up to 90% of nucleotides compared to 65% in room-temperature samples after 24 hours. Some processors now employ instant pasteurization followed by flash freezing to extend shelf life without compromising quality.

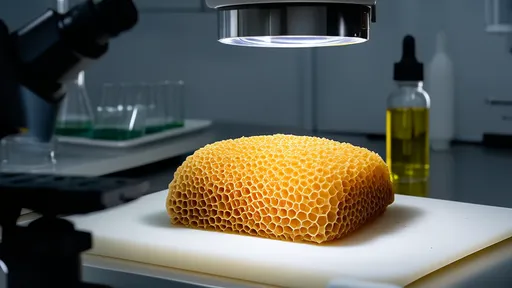

Beyond technical parameters, the mushroom's cultivation conditions profoundly impact extractability. Winter-harvested shiitakes grown on hardwood logs show 50% higher nucleotide content than summer varieties cultivated on synthetic substrates. This variability necessitates batch testing—a practice adopted by premium producers but often overlooked in commodity processing.

The economic implications are substantial. With umami ingredients commanding premium prices in the flavor industry, a 10% improvement in extraction efficiency can translate to millions in annual savings for large-scale producers. However, the push for higher yields must be balanced against energy costs, especially for novel methods like UAE that require specialized equipment.

Looking ahead, the integration of AI-powered process optimization and sustainable extraction solvents like subcritical water may redefine efficiency benchmarks. As demand for clean-label umami enhancers grows, mastering nucleotide extraction from this humble fungus will continue to shape the future of savory flavors.

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025

By /Jul 17, 2025